How Long for Poly Bushings to Break In? A Complete Guide

Polyurethane (poly) bushings are a popular upgrade for vehicles, known for improving handling and providing better performance over traditional rubber bushings. However, many car enthusiasts often wonder: “How long for poly bushings to break in?” Understanding the break-in period, its importance, and how to properly maintain poly bushings can ensure optimal performance and longevity.

In this guide, we’ll explore everything you need to know about poly bushings, including how long they take to break in, what to expect during the process, and tips for maintaining them.

What Are Poly Bushings?

Before diving into the break-in process, it’s important to understand what poly bushings are and why they’re used. Polyurethane bushings are suspension components that replace the factory-installed rubber bushings in your vehicle. They provide a firmer, more durable alternative to rubber, which is prone to wear and deterioration over time.

Why Choose Poly Bushings Over Rubber?

- Durability: Poly bushings are more resistant to wear, UV damage, and chemicals than rubber bushings.

- Improved Handling: The stiffer material reduces unwanted flex in the suspension, leading to sharper handling and better cornering performance.

- Longevity: Polyurethane bushings typically last longer than rubber bushings, which can crack or degrade over time due to heat and moisture exposure.

How Long for Poly Bushings to Break In?

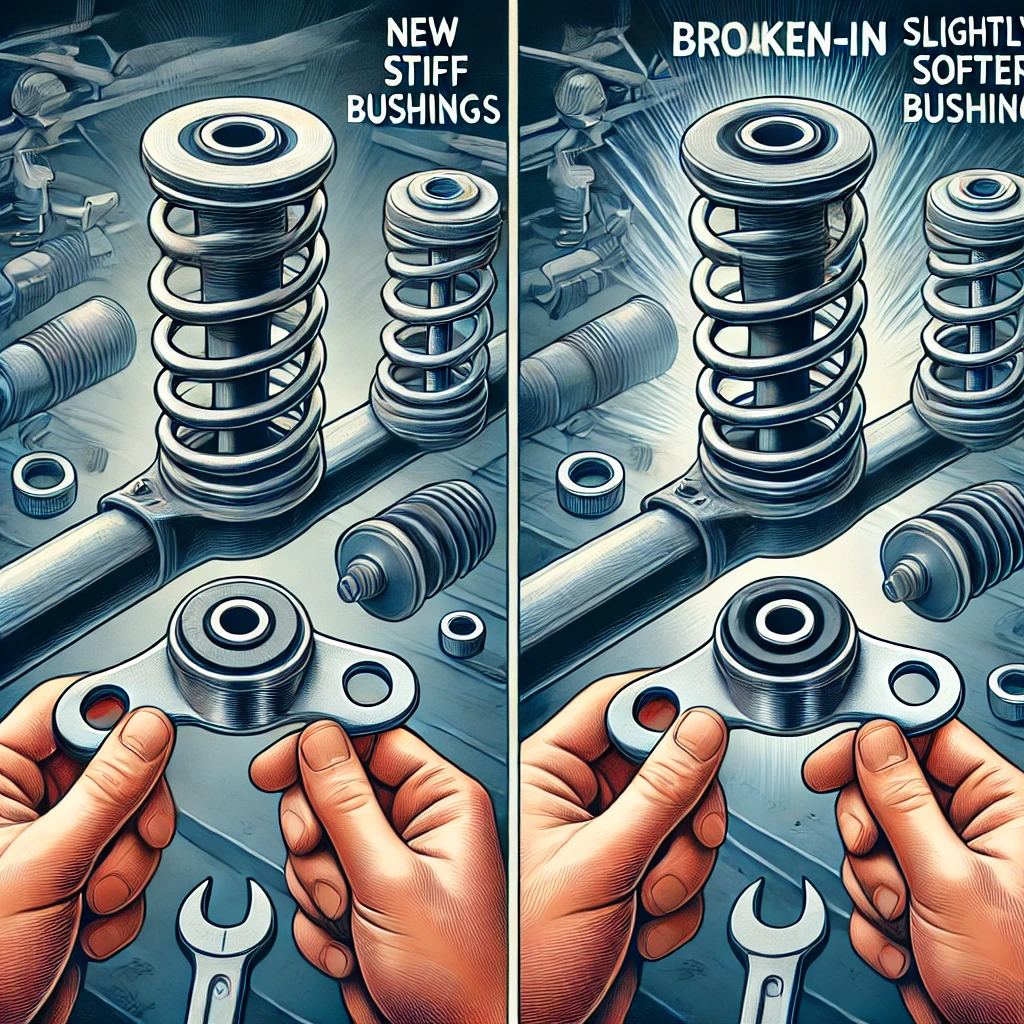

The break-in period for poly bushings is typically 500 to 1,000 miles of driving. During this time, the bushings settle into place and conform to the suspension’s moving parts. This process ensures that the bushings function optimally and provide the improved handling characteristics you’re seeking.

What Happens During the Break-In Period?

During the initial break-in period, poly bushings may feel stiffer than expected. This is normal and part of the process. As you drive, the bushings will begin to soften slightly, molding to the specific contours of your vehicle’s suspension components. This results in smoother performance over time.

- Initial stiffness: When first installed, the bushings may feel rigid, which can lead to a more noticeable ride over bumps.

- Slight noise: You may hear some squeaking or creaking during the break-in phase, especially if the bushings were not lubricated properly during installation.

- Improved handling: After the break-in period, handling will typically feel more responsive, as the bushings have settled into their final position.

Factors That Affect the Break-In Time for Poly Bushings

The exact time it takes for poly bushings to break in can vary based on several factors:

1. Type of Vehicle

The weight and design of your vehicle can affect how long it takes for the bushings to break in. Heavier vehicles may experience a shorter break-in period due to the increased load on the bushings.

2. Driving Conditions

Driving conditions play a significant role in the break-in process. If you’re driving in stop-and-go traffic or primarily on rough roads, the bushings may break in more quickly. On the other hand, smoother highway driving may result in a longer break-in period.

3. Installation Process

Proper installation is key to ensuring an efficient break-in period. If the bushings are not installed correctly or not lubricated properly, they may take longer to break in or wear unevenly.

4. Lubrication

Polyurethane bushings require specific grease or lubrication to prevent noise and ensure smooth movement. Lack of lubrication can lead to excessive friction, which may prolong the break-in period and cause premature wear.

Signs That Your Poly Bushings Are Breaking In

As you approach the end of the break-in period, you should notice several signs that indicate your poly bushings are breaking in properly:

1. Reduced Noise

If you experienced some squeaking or creaking during the initial phase, you should notice that this noise begins to subside after the first few hundred miles. Proper lubrication helps to prevent this from happening in the first place.

2. Improved Ride Comfort

While poly bushings are designed to be stiffer than rubber bushings, you may notice a slight softening after the break-in period. This doesn’t mean that performance is diminished, but rather that the bushings have settled into place.

3. Consistent Handling

Once the bushings have broken in, the handling of your vehicle should feel consistent. Steering will be more responsive, and you may notice improved control when cornering or driving on rough roads.

How to Maintain Poly Bushings After the Break-In Period

Once your poly bushings have broken in, proper maintenance is essential to extend their lifespan and ensure optimal performance. Here are some key maintenance tips:

1. Regular Inspection

Check your poly bushings periodically for signs of wear, such as cracks, deformation, or excessive noise. While poly bushings are more durable than rubber, they can still wear down over time, especially if exposed to extreme conditions.

2. Lubrication

Proper lubrication is crucial for preventing noise and ensuring the smooth movement of poly bushings. Use a silicone-based grease specifically designed for polyurethane bushings to avoid drying or cracking.

- When to Lubricate: It’s recommended to reapply lubrication every 10,000 to 20,000 miles, depending on your driving conditions and the manufacturer’s recommendations.

- How to Lubricate: Clean the bushings thoroughly before applying fresh grease to ensure no debris or dirt is trapped inside.

3. Avoid Harsh Chemicals

Polyurethane bushings are resistant to many chemicals, but harsh substances like petroleum-based lubricants or cleaning agents can degrade the material over time. Always use products designed for poly bushings to avoid damage.

4. Driving Conditions

Excessive exposure to dirt, mud, and water can accelerate the wear of your poly bushings. If you frequently drive off-road or in harsh conditions, be sure to inspect and clean the bushings more regularly.

Common Myths About Poly Bushing Break-In

There are several misconceptions surrounding the break-in process for poly bushings. Let’s clear up some of the most common myths:

1. Myth: Poly Bushings Don’t Need to Break In

Some people believe that poly bushings are ready to perform at their best immediately after installation. However, like most suspension components, poly bushings require a break-in period to fully settle into place and deliver optimal performance.

2. Myth: Noise During Break-In Is a Sign of a Problem

Squeaking or creaking during the initial break-in period is common and not necessarily a sign of improper installation. However, if the noise persists long after the break-in period, it could indicate a lack of lubrication or misalignment.

3. Myth: Poly Bushings Will Always Be Noisy

While poly bushings can make more noise than rubber bushings, especially during the break-in period, proper lubrication can significantly reduce or eliminate this issue. Regular maintenance helps keep poly bushings quiet and efficient.

Benefits of Poly Bushings After the Break-In Period

Once your poly bushings are fully broken in, you’ll start to enjoy a variety of performance benefits:

1. Improved Handling and Control

The stiffer design of poly bushings reduces the flex that is common with rubber bushings, leading to more precise handling and improved control during cornering, braking, and acceleration.

2. Longer Lifespan

Compared to rubber bushings, polyurethane bushings are more resistant to heat, moisture, and chemicals, making them last significantly longer. With proper maintenance, poly bushings can last up to 5-10 years or longer, depending on driving conditions.

3. Enhanced Performance

After the break-in period, poly bushings provide enhanced performance, especially for high-performance or off-road vehicles. The increased rigidity improves the vehicle’s responsiveness, making it feel more connected to the road.

Conclusion: How Long for Poly Bushings to Break In?

In conclusion, the typical break-in period for poly bushings is between 500 and 1,000 miles, depending on factors like driving conditions, vehicle type, and installation quality. During the break-in period, you may experience some initial stiffness or noise, but these issues should resolve as the bushings settle into place.

Proper maintenance, including regular lubrication and inspection, can ensure that your poly bushings provide years of enhanced performance and durability. By understanding the break-in process and following these maintenance tips, you can get the most out of your poly bushings and enjoy smoother, more responsive handling.